Fistreem International specialises in manufacturing water purification products. The Cyclon and Calypso water Stills are known globally for producing reliable Type II water in labs. To support these systems, Fistreem offers a range of pretreatments.

What is water pretreatment?

Pretreatment is the process of removing pollutants from water. Once it is clean, it is moved into the Still to be processed before it is ready to be used in the laboratory. It is important to pretreat water to avoid problems caused by contaminants and to reliably generate large volumes of water sufficient for a wide range of low-purity applications.

Why use pretreatment?

Water is the most widely used reagent in the laboratory, used for everything from rinsing glassware to making biological media and buffers. It can also provide pure water for lab equipment such as autoclaves and dishwashers. So, it is vital to have a reliable source, which is why you should pretreat your tap water before it is fed through your water purification system.

Impure water can have a negative impact on laboratory experiments, resulting in a loss of accuracy and precision. To obtain higher water purity, it is necessary to have a lab water purification system. In a high water-using lab, you may need a reservoir to store the water ready for use.

If you live in a hard water area, the potable water source will contain the ions calcium and magnesium, which leads to limescale. A buildup of limescale can cause your water purification system to work less efficiently and, therefore, compromise the purity of the water produced. Pretreatment reduces the amount of limescale and results in fewer maintenance issues, less downtime and reduced cleaning, ensuring you always have pure water available for your experiments.

Types of pretreatment

Fistreem offers a range of pretreatment options depending on your tap water quality and purity needs.

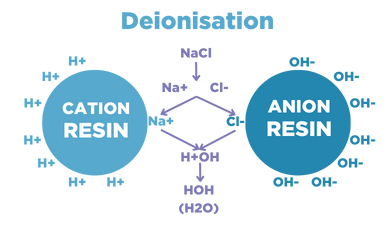

Ion exchange disposable cartridge systems are commonly used as a pretreatment. Various cartridge systems are available, such as the Fistreem Hydros deioniser and Cascade system. Deionisation systems work by replacing negative and positive molecules in water with hydrogen (positive) and hydroxyl (negative) molecules. This is achieved by chemically using synthetic ion-exchange resins to remove ions from feedwater. As the water passes through, hydrogen and hydroxide ions exchange for dissolved minerals and then recombine to form water.

Ion exchange disposable cartridge systems are commonly used as a pretreatment. Various cartridge systems are available, such as the Fistreem Hydros deioniser and Cascade system. Deionisation systems work by replacing negative and positive molecules in water with hydrogen (positive) and hydroxyl (negative) molecules. This is achieved by chemically using synthetic ion-exchange resins to remove ions from feedwater. As the water passes through, hydrogen and hydroxide ions exchange for dissolved minerals and then recombine to form water.

Carbon filtration is another typically used method to remove organic compounds and free chlorine and chloramines from feed water. Activated carbon reduces free chlorine to chlorine and carbon dioxide. It also breaks down chloramines by a catalytic reaction to produce ammonia, nitrogen and chloride. Available as disposable pretreatment cartridges for the Cascade system, it offers a cost-effective way of removing organic impurities from your potable source.

Cartridge systems are ideal as standalone systems for supplying purified water for general laboratory equipment such as CO₂ incubators, environmental chambers, and water baths or when connected to a water purification system.

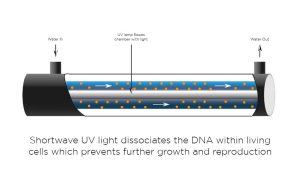

UV sterilisation is a method of pretreatment used to remove bacterial impurities from your water source. UV is typically used to disinfect water. Two wavelengths commonly used are 185nm and 254nm.

UV sterilisation is a method of pretreatment used to remove bacterial impurities from your water source. UV is typically used to disinfect water. Two wavelengths commonly used are 185nm and 254nm.

- 254nm UV with a robust bacterial action, damaging DNA and RNA polymerase at low doses and preventing replication.

- UV light at 185nm strongly oxidises, breaking down large organic molecules into smaller ionised components, ultimately CO₂.

A UV chamber typically consists of a UV lamp mounted in a quartz tube in the centre of a stainless-steel tube. Water then flows through the zone between the quartz and the steel tubes.